About Our Products

Shipton and Heneage shoes are made from top quality materials and traditional craftmanship to achieve a lasting wear and fit - the manufacturing process can involve 200 operations on up to 30 individual pieces of leather. The whole process of making a top quality pair of shoes can take 6 weeks.

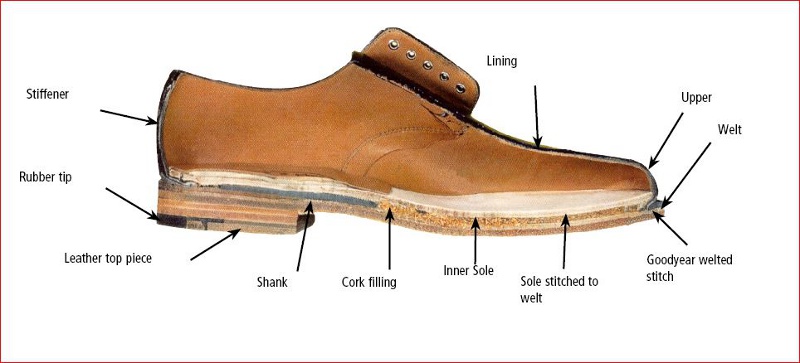

| Stage 1- a pair of uppers is cut from full grain leather, (in essence the external covering of the shoe). A design is punched into the cap and vamp. This is done by hand on the "clickers" bench. Special dyes reveal the rich detail of the leather. | Stage 2 - takes place in the closing department where the cut uppers are assembled, linings and interlinings inserted and stitching applied. |

Stage 3 - using a "last" (a wooden model of the shoes shape) the welt or leather base is stitched to the upper, then the leather outer sole is stitched to the welt - a long-winded process and the mark of a true quality shoe. |

Goodyear welting? What is it?

Goodyear welting is a process patented by Mr Goodyear. He realised that the upper could only be stitched onto a sole a very few times before it was ruined. He invented a process where the upper was stitched to a sacrificial strip of leather which in turn was stitched to the sole. A Goodyear welted shoe therefore has several lives rather than just one life as you can re-sole the shoe. The welt itself can also be renewed carefully.

Thus when you buy a Goodyear welted shoe, not only are you buying a quality item, you are buying a pair of shoes that, if looked after properly, could last a lifetime.

Blake Stitch? What is it?

Essentially means the Upper is directly stitched onto the sole without the sacrificial Goodyear welt. This potentially allows for a more elegant shoe as the edges can be trimmed much closer. The shoe can still be resoled, but in time the edges of the upper may perish if done badly - there being no sacrificial welt the upper can then no longer be stitched to the sole.